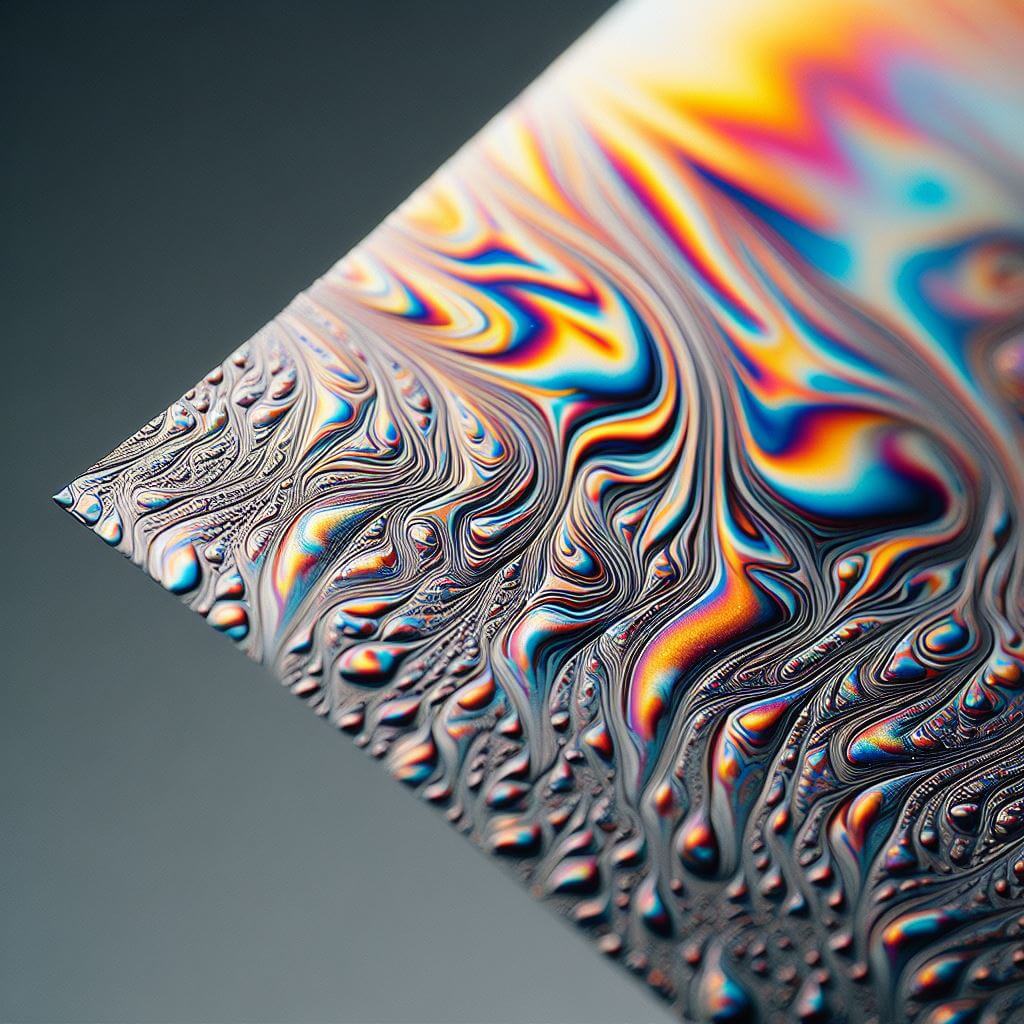

Liquid crystal paper products are at the forefront of digital display technology, offering an amazing combination of flexibility, functionality, and eco-friendly features. These products, such as those used in today’s e-book readers, smart watches, and electronic signage, uniquely embody the idea of paperless communication and information storage. At the heart of these devices is liquid crystal display (LCD) technology, which uses the light-modulating properties of liquid crystals—materials that flow like a liquid but have molecules that can be oriented like a crystal.

Creating products from liquid crystal paper is a difficult task. Manufacturers laminate a thin layer of liquid crystals between two sheets of transparent conductive material, typically indium tin oxide (ITO). This is then covered with protective layers to protect the delicate inner parts from the outside elements. All packaging is designed to be as thin and flexible as possible, thus resembling the look and feel of traditional paper. Unlike regular paper, this innovative product can erase and rewrite information thousands of times without the need for ink or paper, thereby helping to reduce waste.

The principle of operation of these products consists of the selective blocking and transmission of illumination organized by the reaction of liquid crystals to an electric current. This mechanism allows images and text to be displayed that can be easily changed using different electrical signals, making the technology reusable and dynamic.

The appeal of liquid crystal paper products extends to their low energy consumption. Because they can store images without a constant power source, called a “bistable” state, these products are advantageous for applications where frequent updates are not required, such as price tags, or where battery life is a concern, such as electronic books

Despite their apparent ease of use, these complex products hide a complex array of chemicals and materials specifically designed to achieve their impressive functionality. As consumers enjoy the touch and feel of writing or reading from a device that keeps countless trees from turning to paper, the challenge remains to responsibly approach the end-of-life phase of these innovative products.

Consequences of disposal for the environment

The disposal of liquid crystal paper products causes serious environmental problems that require close attention and action. While these high-tech products minimize paper waste and offer several benefits to the user, they can be a hazard to the environment if not disposed of properly. This is due to the complex mix of materials and chemicals that make up every component of devices, from liquid crystal displays to electronic circuits.

When these products reach the end of their shelf life, they transform from a testament to innovation to a waste management puzzle. The environmental consequences are diverse; chief among them is the risk of hazardous chemicals leaching into the ground if these products are disposed of in landfills. Liquid crystals securely locked inside the device during use can become a source of contamination if released into the environment. They may contain substances that, if not properly disposed of, can potentially disrupt ecosystems and enter water sources with the risk of bioaccumulation and adverse effects on wildlife and human health.

The built-in electronic components are a source of concern. Printed circuit boards (PCBs), batteries, and other electronic components often contain heavy metals such as lead, mercury, and cadmium, as well as other toxic substances such as brominated flame retardants. These materials can pose significant risks to the environment, contaminating soil and groundwater, thereby affecting plant and animal life and potentially entering the food chain.

Another aspect of the equation is the resource intensity of electronics production. Mining and processing metals found in liquid crystal paper components can be environmentally taxing, contributing to habitat destruction, water pollution, and greenhouse gas emissions. The lost opportunity to recover resources when products are not recycled further increases the environmental impact. Recycling these products not only prevents harm by ensuring the safe handling of hazardous materials but also helps conserve valuable resources by returning metals and other materials into the production cycle, thus reducing the need to extract new resources.

Given the environmental implications, it is clear that the disposal of liquid crystal paper products requires a strategic approach aligned with e-waste regulations and best practices that prioritize environmental safety. These products must be diverted from the general waste stream and directed to facilities equipped to handle e-waste responsibly. Only with such specialized treatment can the potential negative impact on the environment be mitigated, thus combining the benefits of this remarkable technology with our shared responsibility to preserve the planet for future generations.

Disposal Considerations

The responsible disposal of liquid crystal paper products is a complex task that requires thoughtful planning and understanding from consumers. These devices are not your average piece of refuse and thus cannot be treated as such; instead, they fall under a category colloquially referred to as e-waste. Due to their chemical and material composition, they cannot join the ranks of regular garbage but must be approached with a different strategy altogether.

Many local authorities understand the gravity of indiscriminate e-waste disposal and have responded by enacting legislation that dictates specific disposal methods for such electronics. The legislation serves as a guiding framework for ensuring that these products do not merely end up in landfills where their hazardous components might cause long-term environmental damage. Instead, they mandate proper handling, collection, and treatment procedures that aim to offset the ecological risks associated with improper disposal.

The disposal process begins with segregation. It is incumbent upon consumers to separate their e-waste from their regular household garbage. While this may require additional effort, the payoff in terms of environmental protection is significant. Local waste management services often offer dedicated collection bins or pick-up services specifically for e-waste. Moreover, many electronics retailers and manufacturers take back programs where consumers can return their used liquid crystal paper products and other electronics.

Consumers should be particularly vigilant about unapproved or “informal” e-waste recyclers. Such entities might offer convenient disposal services, but without the guarantee that the items will be handled in an environmentally responsible manner. In some cases, informal recycling operations can lead to severe environmental and human health consequences due to the unsafe extraction of materials, improper handling of toxic substances, and inadequate disposal of residual components.

Recycling

The intricate nature of liquid crystal paper products means that recycling them is no simple feat. It involves a series of carefully conducted procedures aimed at segregating and salvaging the numerous components that these devices are composed of. First, the external housing is removed, often yielding plastics that, once purified, can be melted down and remolded into new products. Then, attention is turned to the more complex task of extracting the liquid crystal display. The layers of glass or plastic, along with the liquid crystals themselves, must be separated from the conductive materials in a way that allows for the reuse or safe disposal of each component.

The PCBs (printed circuit boards) common in these products bear a wealth of precious metals such as gold, silver, and copper, which have substantial recycling value. Through a combination of mechanical and chemical processes, these metals are carefully extracted and repurposed to manufacture new electronic components, thereby closing the loop and significantly reducing the need to mine fresh materials from the earth.

In addition to metals, modern recycling facilities are equipped to handle the various other materials found in these devices. For instance, they can process the layer of ITO – a material that, owing to its qualities as a transparent conductor, is extensively used in the production of LCDs and other touch-sensitive screens. Successful recovery of ITO is an important step, as the mining of indium, one of its main components, is environmentally intensive and increasing in cost due to scarcity.

Yet the challenges associated with the recycling of these products cannot be understated. Their complex manufacturing not only makes the recycling process intricate but also less cost-efficient than for simpler waste materials. This has catalyzed a push for extended producer responsibility (EPR), a policy approach that holds manufacturers accountable for the environmental impacts of their products throughout the product life cycle, including end-of-life management.

EPR policies encourage manufacturers to design products that are easier to recycle and may even have financial implications associated with the collection and processing of their products post-consumer use. The objective of such policies is to reduce the burden on consumers and governments while incentivizing sustainable product design.